Ukugcina AI-Pallet Jackibalulekile ekuqinisekiseni ukusebenza kakuhle nefanelekileyo kwiindawo zokugcina izinto, iifektri, kunye nezinye izinto ezemizi-mveliso. Phakathi kwemisebenzi yolondolozo ebalulekileyo, ukugcina inqanaba le-oyile elifanelekileyo leyona nto iphambili. Esi sikhokelo sigqibeleleyo, siya kuyonakalisa i-oyile ye-oyile ye-jacks kwaye ibonelele ngamanyathelo aneenkcukacha ngendlela yokugcwalisa i-oyile ukugcina izixhobo zakho zigcina izixhobo zakho zigcina izixhobo zakho.

Ukubaluleka kokugcinwa kweoyile:

1. Inkqubo egudileyo: Inkqubo ye-hydraulic ye-jack yePallet ixhomekeke kwioyile yokusebenza ngokufanelekileyo. Amanqanaba oyi-oyile aneleyo aqinisekisa ukuphakama okungenamguuko kunye nokwehlisa iifolokhwe, ekufakweni kwimveliso eyandisiweyo kunye nokusebenza kakuhle kwimisebenzi yokuphatha ngezinto.

2. UKUHLAZIYWA KOKWENZA UMSEBENZI: Amanqanaba e-oli angonelanga anokukhokelela ekunyukeni kwengqumbo kwaye anxibe ngokwamacandelo enkqubo ye-hydraulic, onokubangela ukonakala okanye ukungaphumeleli kwangaphambili. Isondlo se-oyile esiqhelekileyo sinceda ukukhusela ukulungiswa kweendleko kunye ne-downtime.

3. UKHUSELEKO: Igcinwe kakuhle i-pallet jacks ikhuselekile ukusebenza. Ukuqinisekisa ukuba inqanaba le-oyile elichanekileyo linciphisa umngcipheko wokungasebenzi kakuhle okanye ukusilela okungalindelekanga okunokubangela ingozi yokhuseleko kubasebenzi kunye nabasebenzi abakufuphi.

4.1Ngokongela: Iijele ezigcinelwe kakuhle zinobuntu obude benkonzo. Ngokujonga rhoqo kwaye ukhulule ioyile, unokwandisa ixesha lobomi bakho kunye nokwandisa ukubuya kwawo kutyalo-mali.

Isikhokelo senyathelo ngenyathelo lokugcwalisa i-pallet jack i-oyile:

1. Qokelela izixhobo ezifanelekileyo:

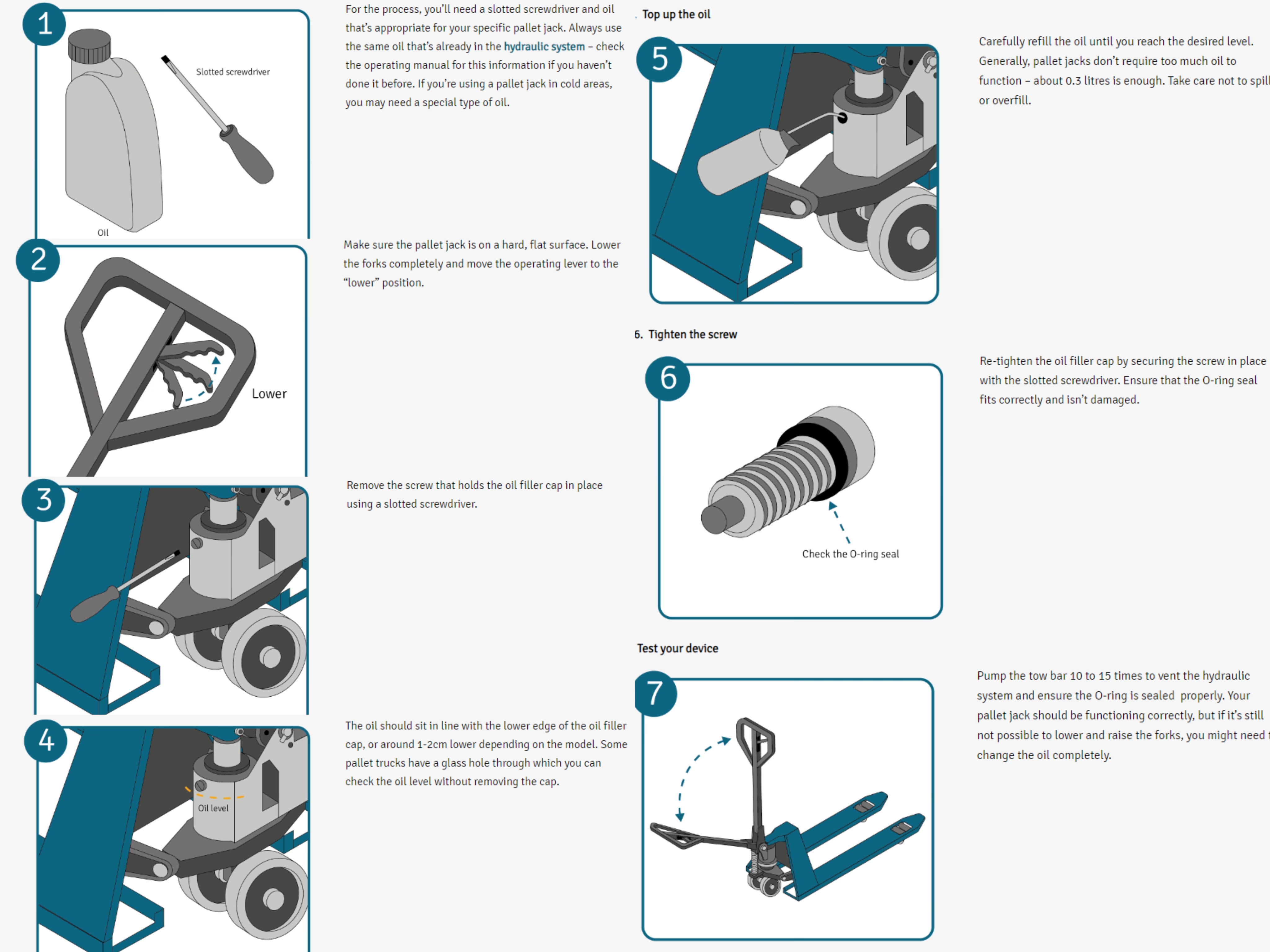

Ngaphambi kokuqala inkqubo ye-oyile, qinisekisa ukuba unezixhobo ezifunekayo kunye nezixhobo. Uya kufuna i-screwdriver enamafutha kunye neoyile efanelekileyo kwiPallet Jack yakho. Jonga kwincwadana yokusebenza yokumisela uhlobo lweoyile efanelekileyo yemodeli yakho ethile.

2. Lungisa i-pallet jack:

Beka i-paller jack kwi-hard, efihlakeleyo ukuqinisekisa uzinzo ngexesha lenkqubo yesondlo. Phantsi iifoloko ngokupheleleyo kwaye usete i-lever esebenzayo kwindawo ethi "esezantsi" yokukhupha nayiphi na ingcinezelo kwinkqubo ye-hydraulic.

3. Fikelela kwi-cap ye-oyile:

Sebenzisa i-screwdriver esketsi ukuba isuse i-screw ebambe i-cap ye-oyile kwindawo. Phakamisa ngononophelo kwi-cap ukufikelela kwindawo yokugcina ioyile.

4. Jonga inqanaba leoyile:

Ngekepusi yeoyile esusiweyo, hlola ixabiso leoyile kwindawo yokugcina amanzi. Ioyile kufuneka ihambelane nomda ongezantsi we-filler cap okanye malunga ne-1-2 i-1-2 ingezantsi, kuxhomekeka kwimodeli ye-pallet jack. Ezinye ii-jacks zePallet zinokuba nefestile ebonakalayo yokutshekisha kwinqanaba leoyile elula.

5. Phezulu ioyile:

Ukuba inqanaba leoyile lingaphantsi koluhlu olucetyiswayo, ligalele ngenyameko kwi-oyile efanelekileyo yeoyile ukufikelela kwinqanaba elifunayo. Kulumkele ukugqobhoza indawo yokugcina indawo, njengoko oku kunokukhokelela kuxinzelelo olukhulu kunye nomonakalo onokubakho kwinkqubo ye-hydraulic. Ngokwesiqhelo, ukongeza malunga ne-0.3 iilitha zeoyile zanele kwii-jacks ze-jacks ezininzi.

I-6. Khusela i-cap ye-oyile:

Nje ukuba ioyile ikhutshiwe, iphinda iphinde iphinde iphinde i-filter filvoir kwaye ikhuseleke endaweni yokuqinisa isikhafu ngesikere esine-screwdriver. Qinisekisa ukuba itywina le-O-i-Oript libekwe ngokuchanekileyo kwaye lingaqhelekanga ukuthintela ukuvuza kweoyile.

7. VavanyaI-Pallet Jack:

Ukuqinisekisa ukutywinwa okufanelekileyo kunye nokusebenza kwenkqubo ye-hydraulic, ipompo i-tow bar 10 ukuya kwezili-15 ukutyhubela nayiphi na umoya obanjiweyo kwaye usasaze i-oyile ngokulinganayo. Vavanya i-pallet jack ngokuthoba nokuphakamisa iifoks ezininzi ukuqinisekisa ukusebenza kakuhle.

Ngokulandela la manyathelo kwaye kubandakanya ukugcina i-oyile yeoyile kwi-oyile kwi-pallet ye-jack ye-jack ye-jack, unokuqinisekisa ukusebenza kakuhle, ixesha elide, kunye nokhuseleko lwezixhobo zakho. Khumbula ukucwangcisa iitshekhi zexesha kunye neendawo eziphezulu zeoyile njengoko kufuneka ukugcina i-pallet jack yakho ye-Deak iminyaka ezayo.

Ukongeza amava obuqu:

Ukongeza kwisikhokelo esibanzi kwi-Pallet Jack Jack i-oyile, ndingathanda ukwabelana ngamava akho abonisa ukubaluleka kokubaluleka.

Kunyaka ophelileyo, ngelixa enyamekela imisebenzi yendlu, ndadibana nemeko apho omnye we-jacks yethu jalt waqala ukufumana ubunzima ekuphakanyisweni kwemithwalo enzima. Ekuqaleni, sakrokrela umbandela woomatshini kwaye safowunela kwi-tetrician ukuba ihlolwe. Nangona kunjalo, kwiimviwo ezisondeleyo, safumanisa ukuba inqanaba leoyile kwinkqubo ye-hydraulic laphantsi kakhulu.

Ukucamngca ngesi siganeko, ndaqonda ukuba sikugawule ukubaluleka kokugcinwa kweoyile rhoqo. Ngaphandle kokuba neshedyuli yesondlo, kwakulula ukuphosa imiqondiso efihlakeleyo yeoyile, ngakumbi ngexesha lexakekile. Oku kongamela kuphela kwakhokelela kwixesha lokuphumla okungalindelekanga kodwa kwanezinto ezongezelelekileyo zokulungisa ezinokuthi zithintelwe ngolondolozo olululo.

La mava asebenza njengesifundo esibalulekileyo kwiqela lethu, egxininisa indima enkulu yendlela yokulungisa. Ukususela ngoko, sisebenzise iiprothokholi zolondolozo lweoyile, kubandakanya iitshekhi zenqanaba le-oyile eziqhelekileyo kunye namanqanaba acwangcisiweyo. Ngokuhlala uphaphile kwaye usebenza, sikwazile ukuthintela izehlo ezifanayo kunye nokuqinisekisa ukusebenza okungaphazanyiswa kwiziko lethu.

Ngokwabelana ngale anecdote yobuqu, ndiyathemba ukuba ndingaphantsi kweyona nto ibalulekileyo yokugcina ioyile kwaye ndikhuthaze abanye ukuba babeka phambili le nkalo ibalulekileyo ye-Pallet Jack Care. Ngokukhuthala iinkcukacha kunye nokuthathela ingqalelo kwiinkcukacha, sinokuthobeka umngcipheko, izixhobo zokwandisa ixesha lobomi base-Wissepan, kwaye sigcine indawo ekhuselekileyo nefanelekileyo yokusebenza.

Ixesha lasemva: Mar-27-2024